Products & Services

PRODUCTS

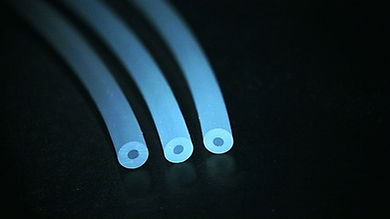

Our expertise includes extruding tubing like single lumen, multi-lumen upto 8 lumens, multi bore, dual lumen, intricate profiles and shapes using wide range material like Pebax®, PVC, LDPE, HDPE, PE, PU, Nylon, PEEK, PP, Polyimide.

Polyvinyl chloride (PVC)

DEHP free material also available

Capable diameter range:

From ID 0.4 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range : Min of 0.1 mm.

Low Density Polyethylene (LDPE)

Capable diameter range:

From ID 1 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.1 mm.

Polypropylene (PP)

Capable diameter range:

From ID 1 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.07 mm.

High density polyethylene (HDPE)

Capable diameter range:

From ID 1 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.1mm.

Thermoplastic Polyurethanes (TPU)

Capable diameter range:

From ID 0.4 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.1mm.

Poly carbonate (PC)

Capable diameter range:

From ID 1 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.5mm.

Thermoplastic elastomer (TPE)

Capable diameter range:

From ID 0.4 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.1mm.

Acrylonitrile butadiene styrene (ABS)

Capable diameter range:

From ID 1.0 mm to 25 mm OD with tolerance of ± 0.05 mm.

Capable Wall thickness range: 0.1mm.

HDPE-LDPE MIXED (HD-LD MIX)

From ID 1 mm to 25 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.1mm.

Pebax

From ID 0.5 mm to 10 mm OD with tolerance of ± 0.0254 mm.

Capable Wall thickness range: 0.05mm.

EXTRUSION CAPABILITIES

Boasting An Impressive Prototype Turnaround Time Of 2 Business Weeks, We Expedite The Development Process. Nevertheless, Extended Lead Times May Be Applicable Depending On The Complexity Of The Product Or Material Involved.

Special Shapes

Thermal Bonding Extruded Tubes

Multi Bore

Multi Lumen Tube

Co-Extrusion

Radio-Opaque Lined Tubes

ASSEMBLY CAPABILITIES

We Undertake Assemblies Of Medical Devices Components And Offer An Array Of Secondary Operations Like:

Draw-Down/Tapering.

Bevelling .

Etching & Pad Printing.

Drilling, Flaring And Flanging.

Heat Sealing.

Heat Shrinking.

Scoring, Slitting And Stripping.

Heat Forming.

Tube Tipping, Tube Bending & Punching.

Tube Bonding Like Solvent Bonding, Adhesive Bonding, Uv Bonding.

Induction Bonding & Thermal Bonding.